Content:

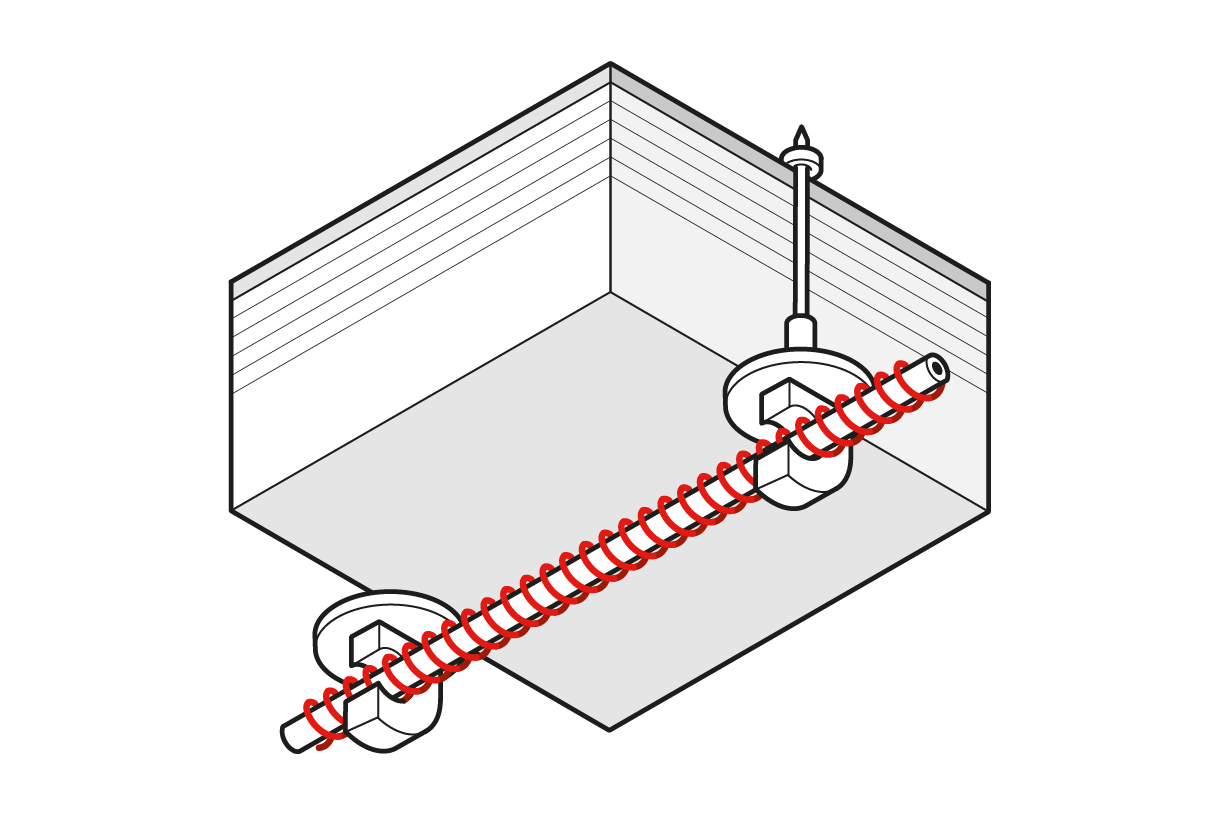

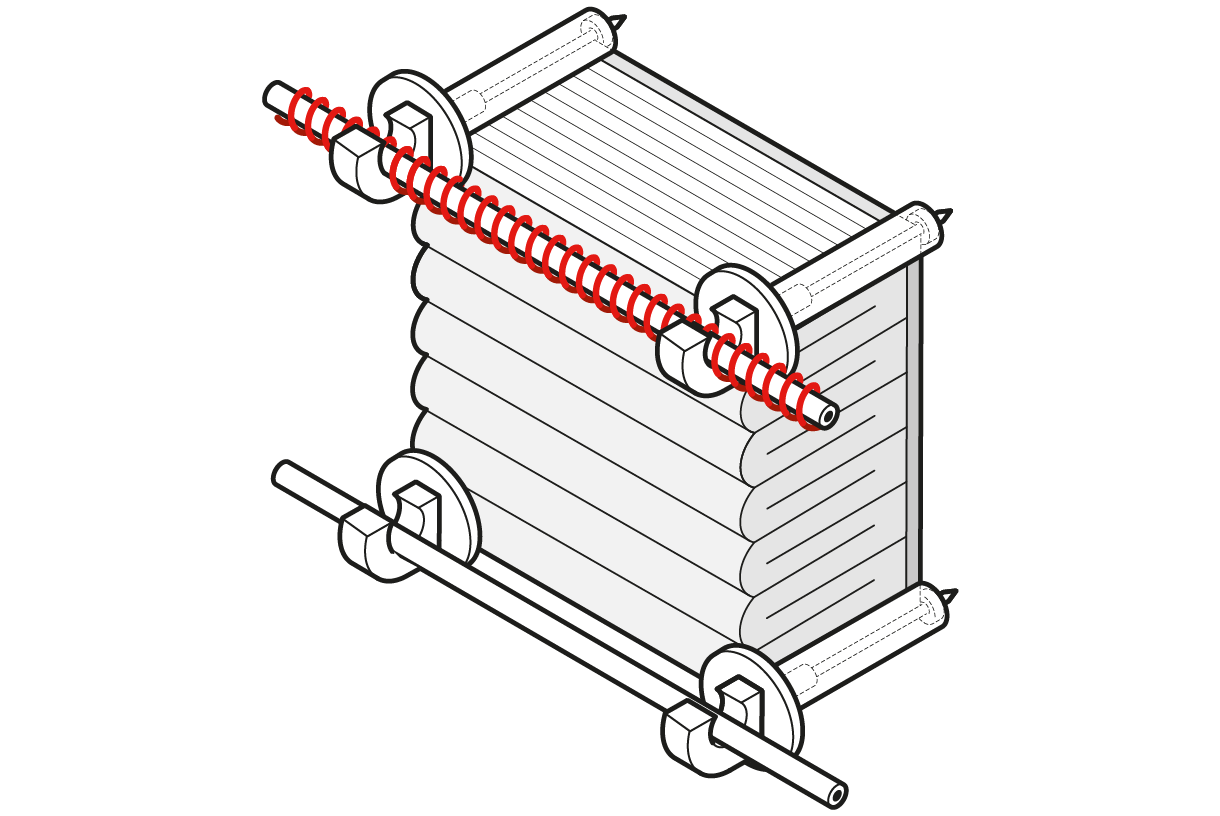

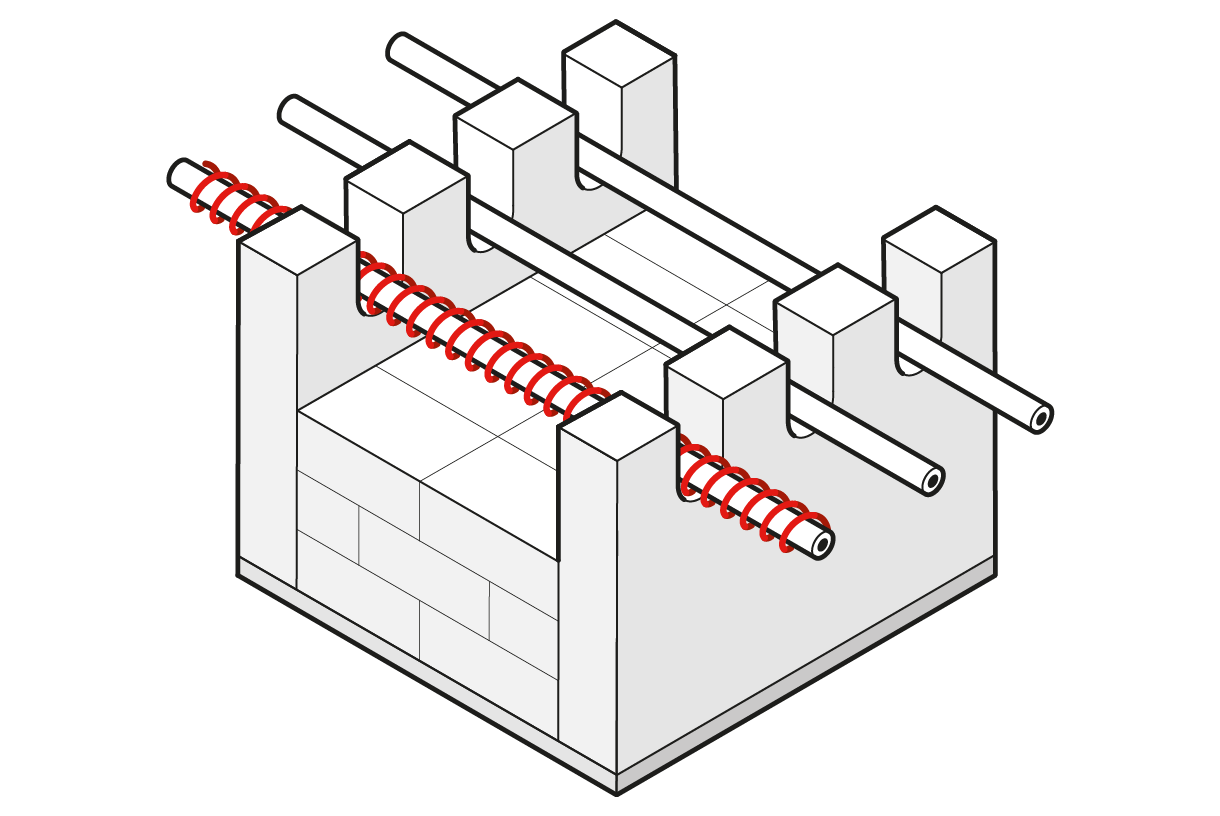

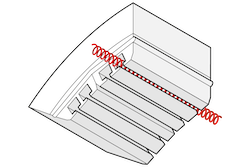

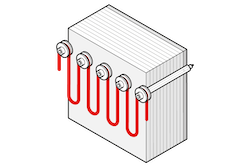

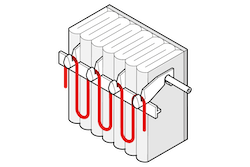

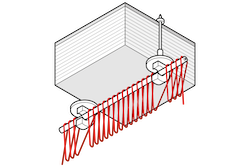

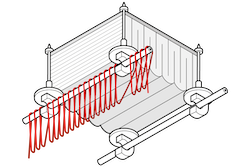

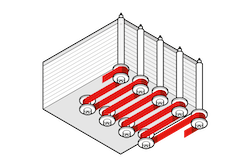

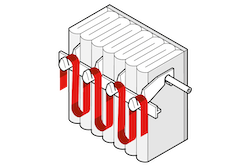

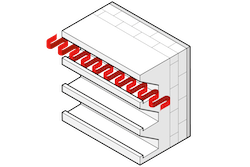

Wire: Spirals - free radiating

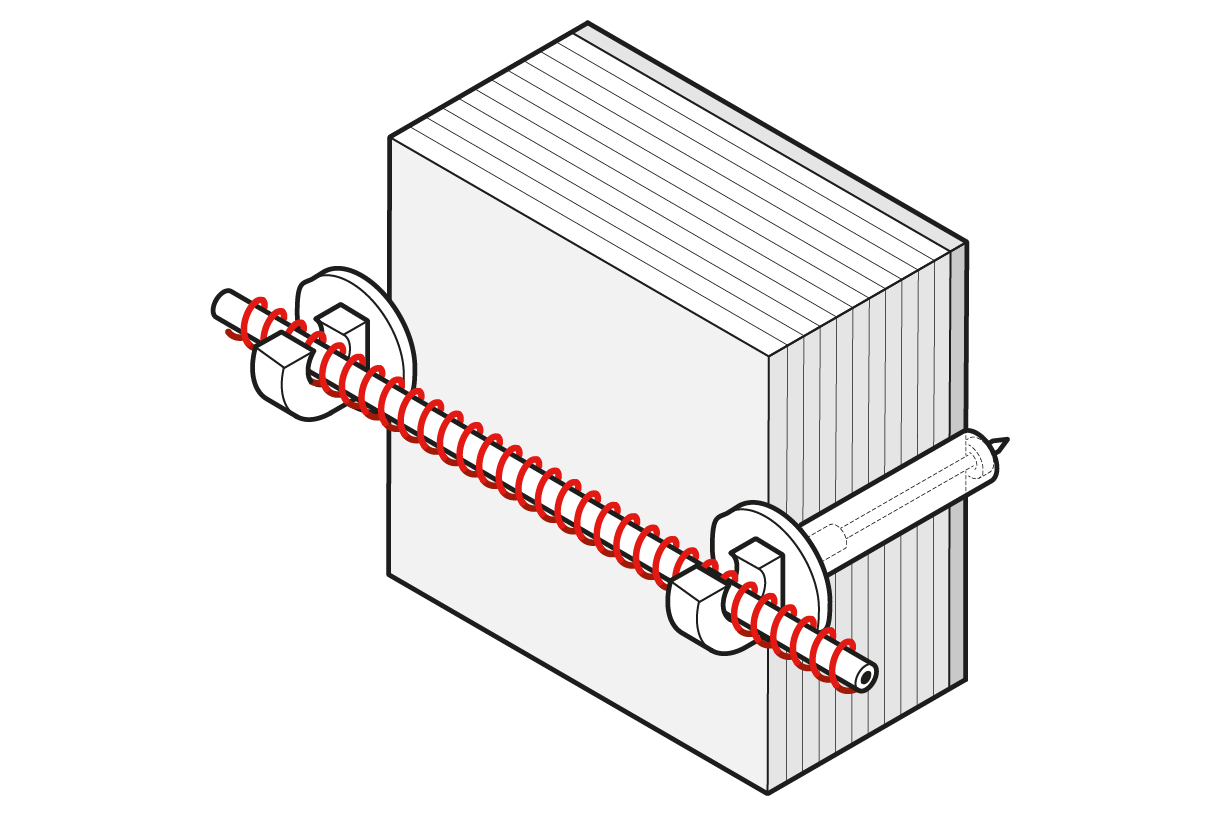

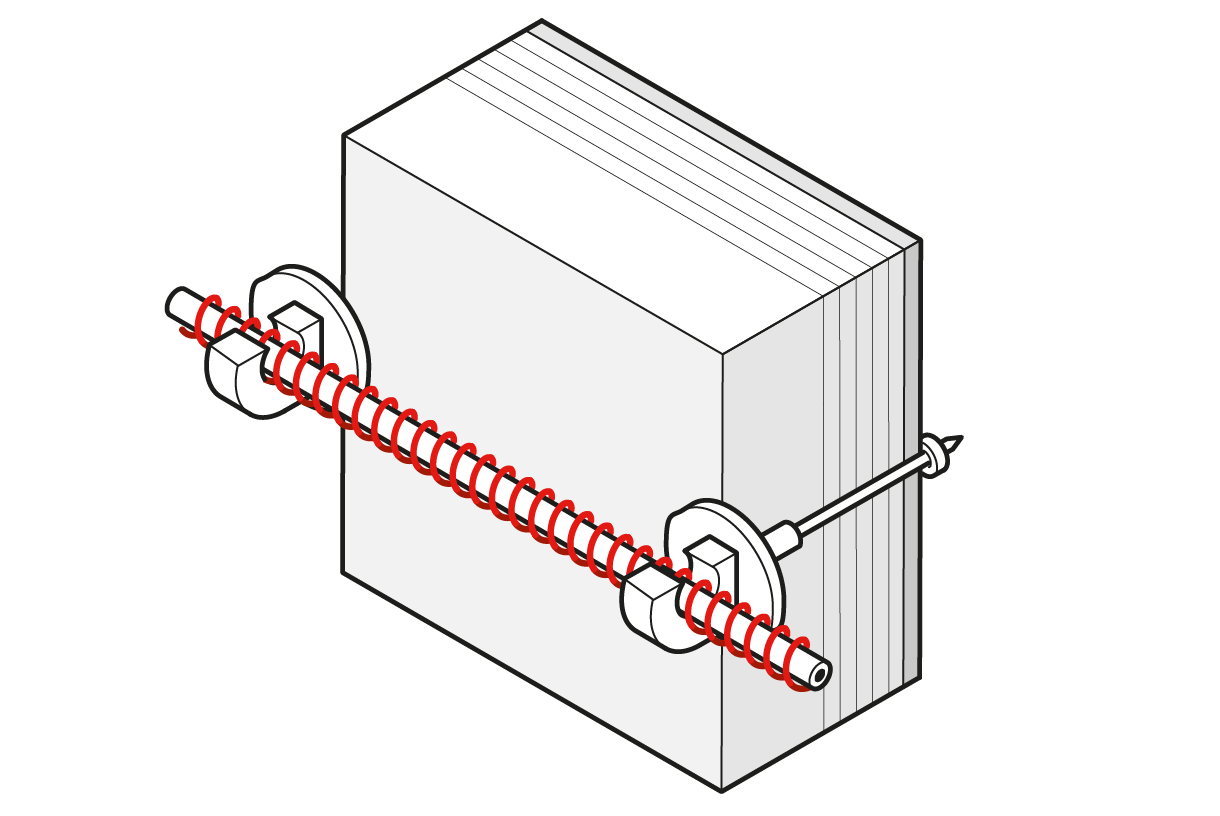

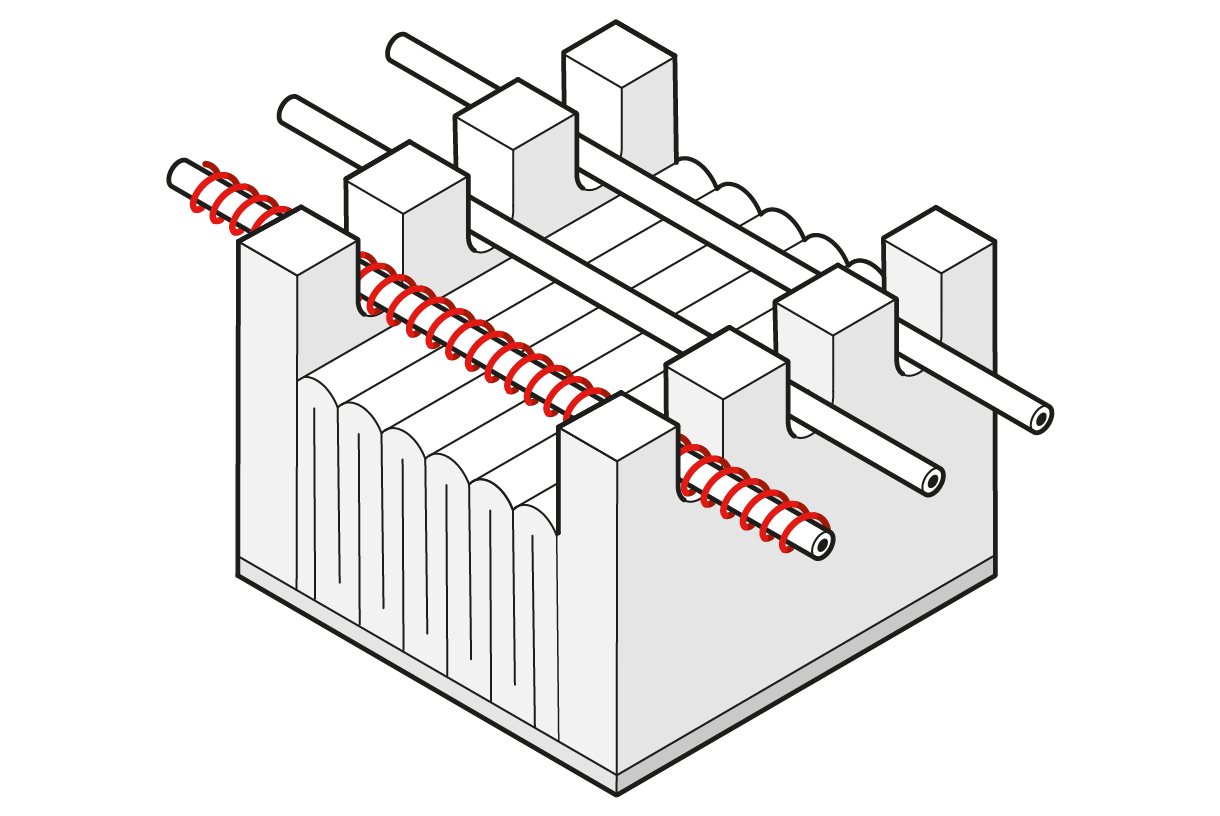

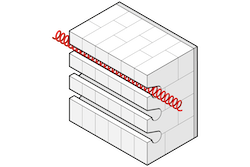

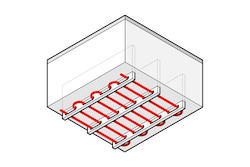

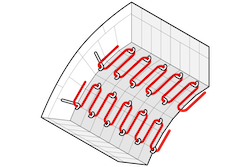

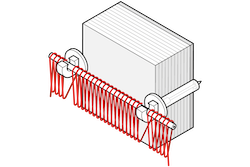

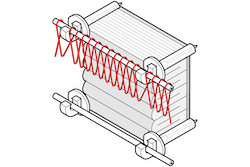

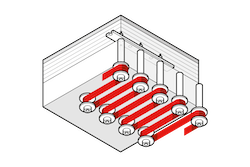

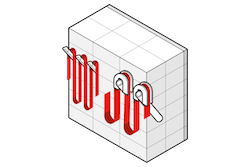

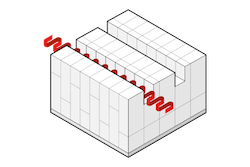

Wire: Spirals

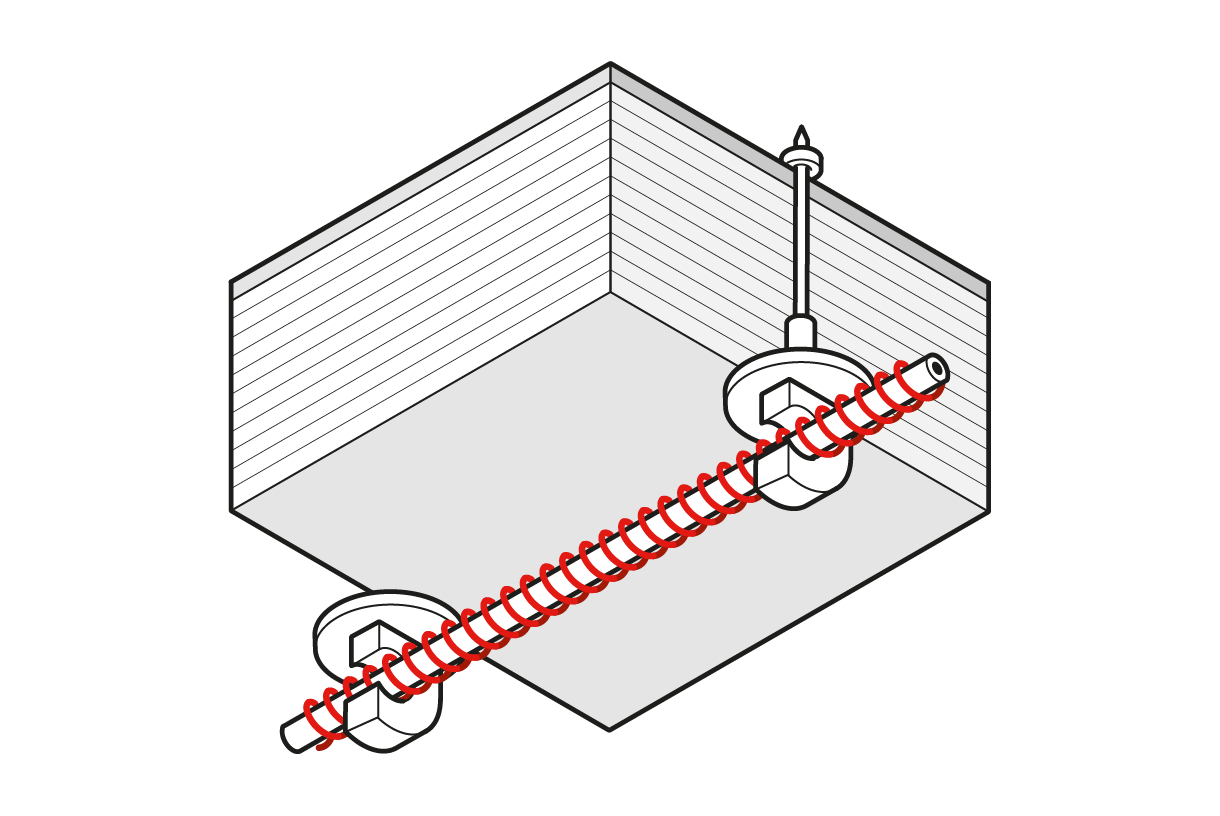

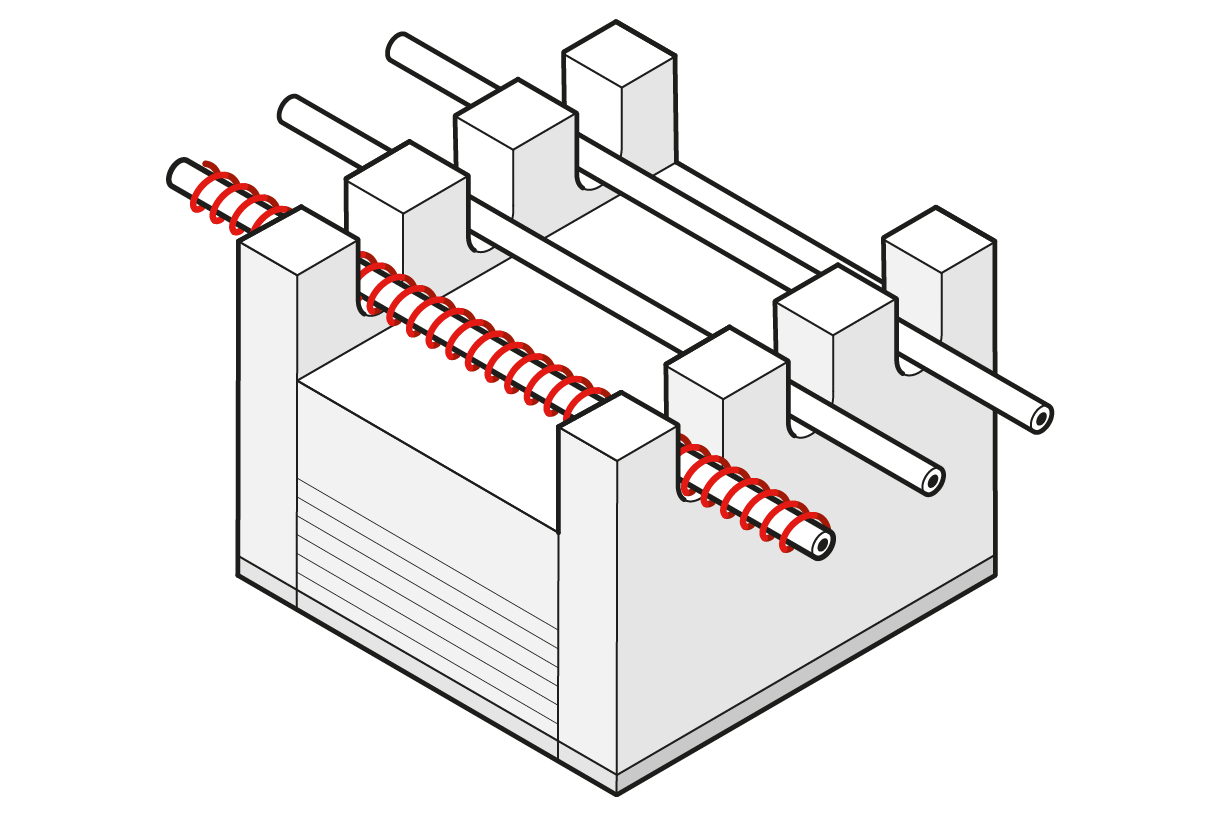

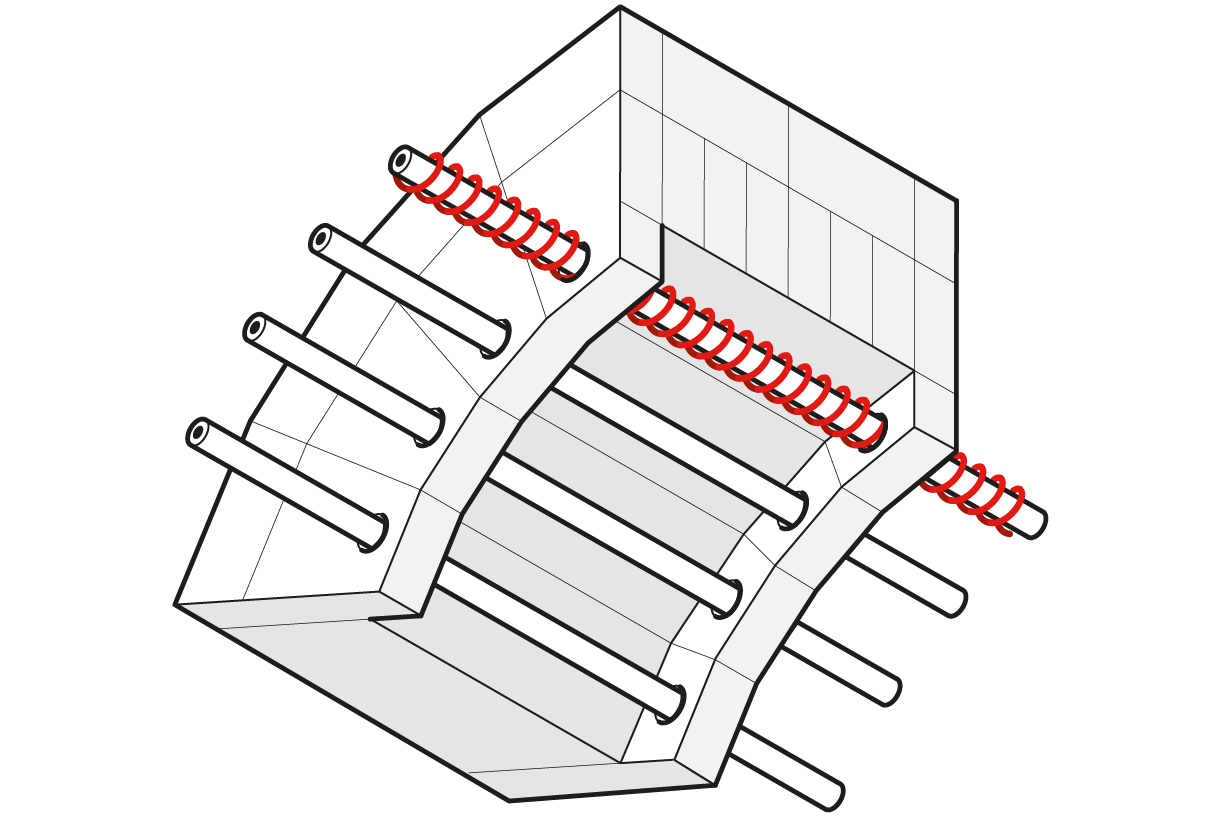

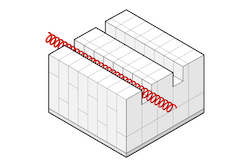

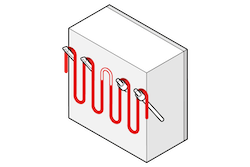

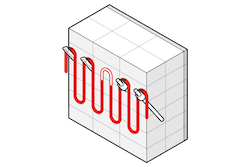

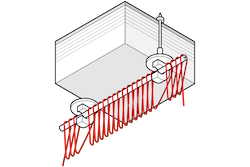

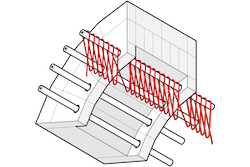

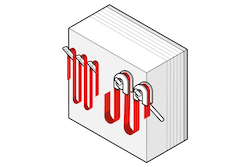

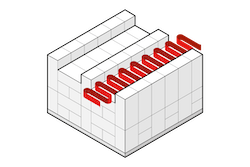

Wire: Rob

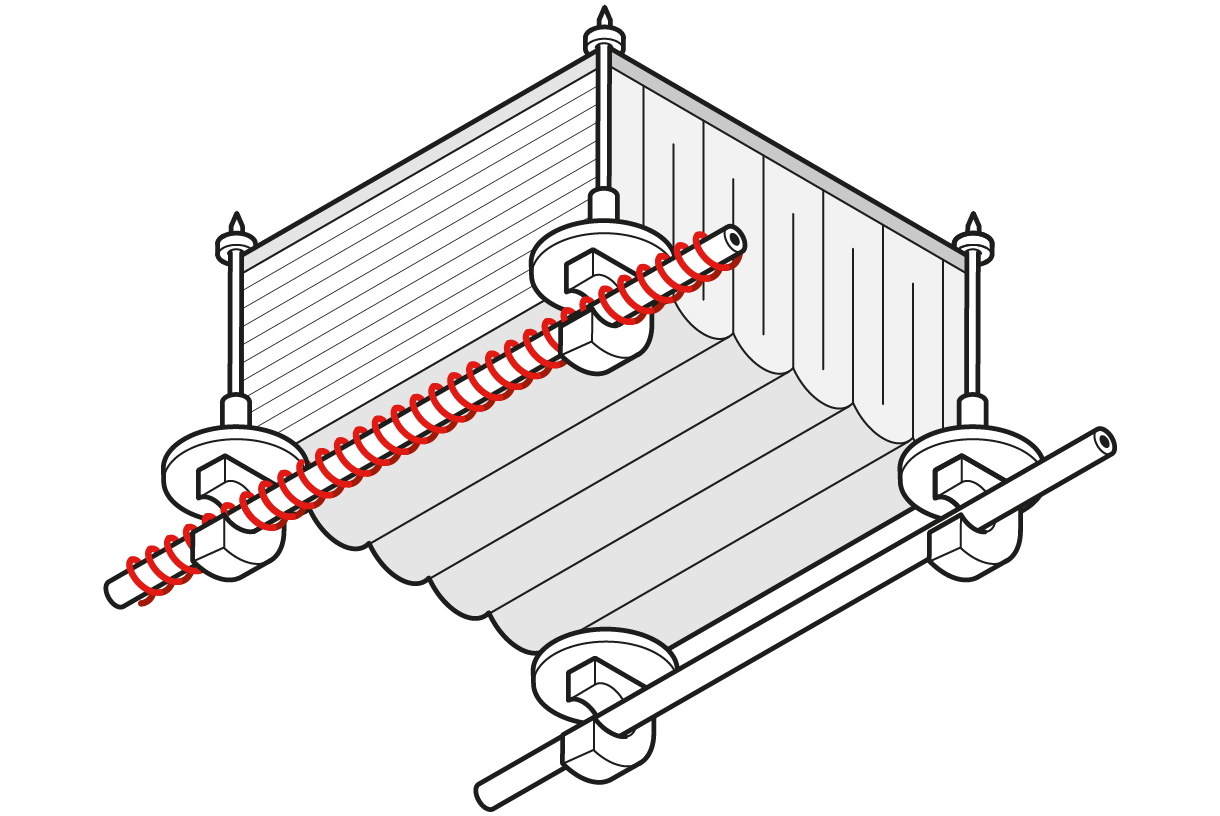

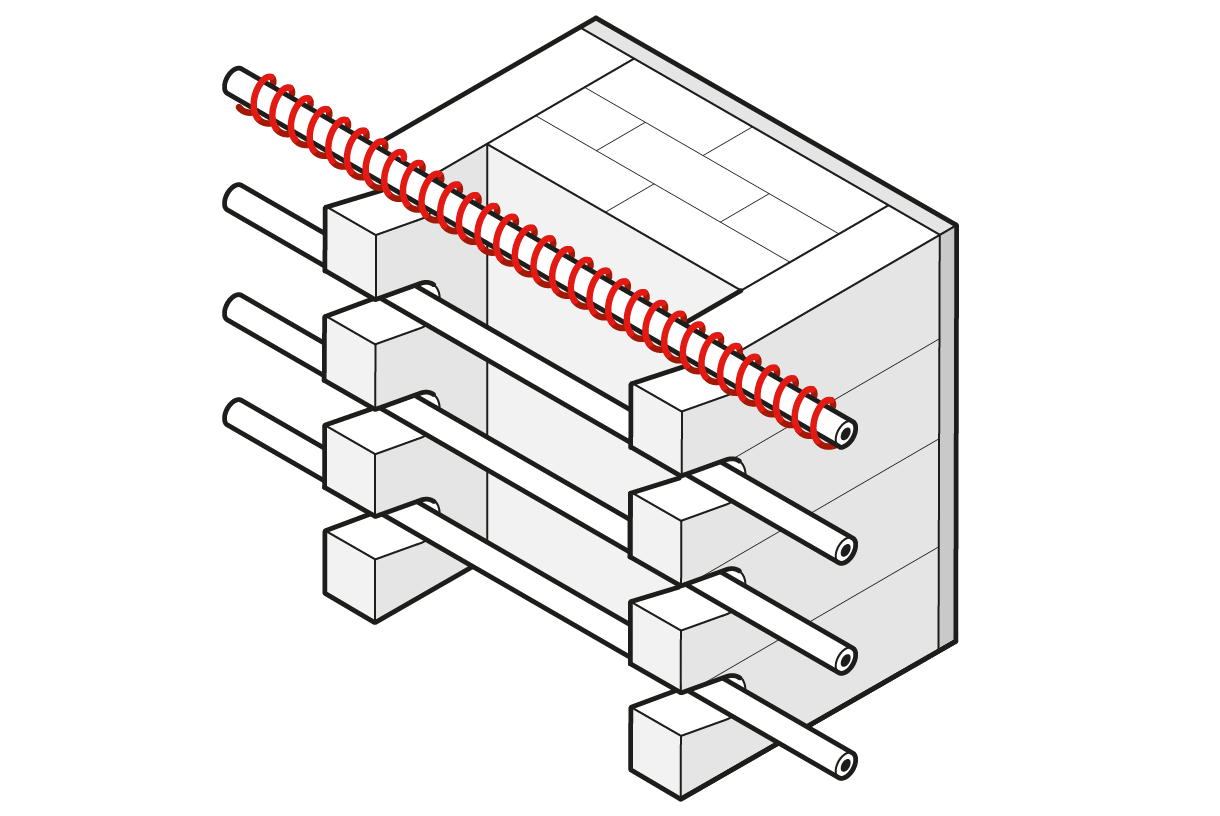

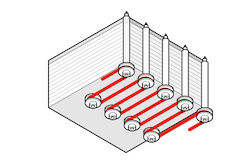

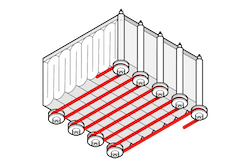

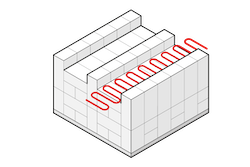

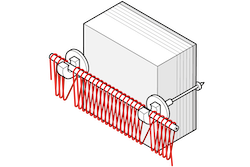

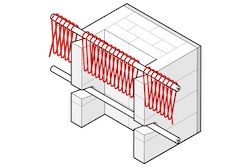

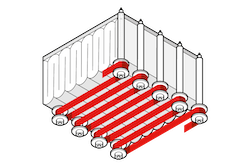

Wire: Loop

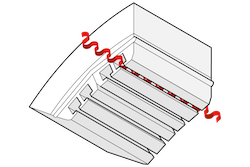

Strip: Corrugated - free radiating

Strip: Corrugated

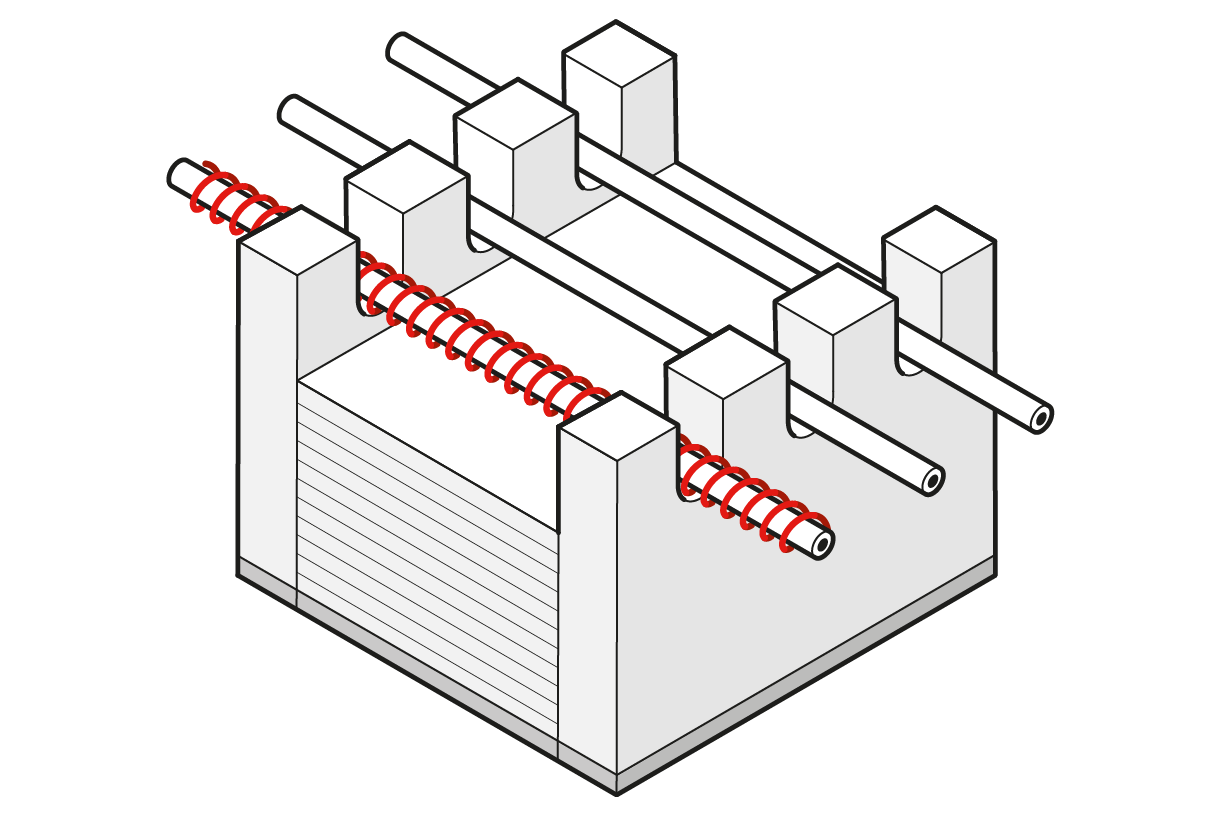

USE OF CERAMIC SUPPORT MATERIALS

The ceramics used in furnace construction significantly affect furnace life, operating properties, and thermal efficiency. High-quality refractory element supports are crucial for the durability and operating life of heating elements. Only high-grade fireclay or sillimanite with an alumina content over 45%, iron oxide content under 1%, and minimal alkali content should be used. The ceramic support material must have high insulation resistance and withstand rapidly fluctuating thermal and mechanical stresses.

Heating elements are sensitive to impurities on ceramic supports, which may lead to creep currents that attack the elements and cause premature failure. These impurities may also react with the surface oxide, reducing element life. It is essential to keep the supporting bricks clean. After an element failure, any damaged brick should be replaced or coated with protective cement.

FURNACE INSULATION MATERIALS

In modern industrial furnaces, ceramic fiber insulation is commonly used, initially in “blankets” attached to the furnace using studs and washers. Over time, other fiber materials, such as panels and vacuum-formed modules, have been introduced, offering benefits like energy savings, quick furnace reaction, and lightweight design. Traditional brick lining, however, has advantag- es, such as superior mechanical properties.

WIRE: SPIRALS - FREE RADIATING |

|||

| Fiber-blanket |  |

|

|

| Fiber-vacuum formed |  |

|

|

| Fiber-stacked |  |

|

|

| Brick |  |

|

|

WIRE: SPIRALS |

|||

| Fiber-blanket |  |

|

|

| Fiber-vacuum formed |  |

|

|

| Fiber-stacked |  |

|

|

| Brick |  |

|

|

WIRE: ROB |

|||

| Fiber-blanket |  |

|

|

| Fiber-vacuum formed |  |

|

|

| Fiber-stacked |  |

|

|

| Brick |  |

|

|

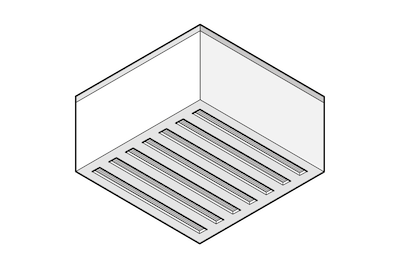

WIRE: LOOP |

|||

| Fiber-blanket |  |

|

|

| Fiber-vacuum formed |  |

|

|

| Fiber-stacked |  |

|

|

| Brick |  |

|

|

| Fiber-blanket |  |

|

|

| Fiber-vacuum formed |  |

|

|

| Fiber-stacked |  |

|

|

| Brick |  |

|

|

| Fiber-blanket |  |

|

|

| Fiber-vacuum formed |  |

|

|

| Fiber-stacked |  |

|

|

| Brick |  |

|

|